A deburring machine with high operability

that can be processed on any material

We can design and manufacture electrolysis equipment that includes material supply/

removal (cleaning process/rust prevention process) according to configuration of the customer's production line.

Electro Chemical Deburring Machines

ECMB-N2Electrolytic Deburring Equipment

Product line-up

ECMB-N2(Latest Model)

ECMB-N1

ECMB-OH

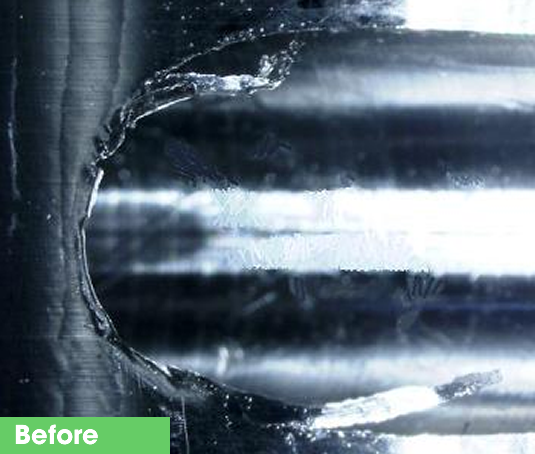

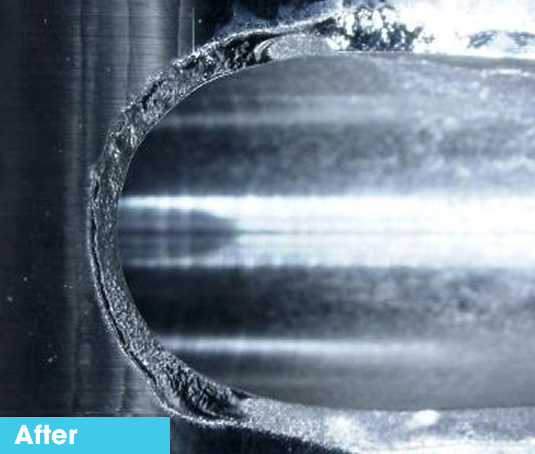

Example of processing

What is The Electrolytic Chemical Deburring Equipment?

This is an equipment that removes burrs by applying electrolysis reduction using a dedicated electrode jig that is uniquely designed according to the customer's work piece.

Strengths of an electrolytic chemical deburring equipment

Achieves cross hole deburring

Even in narrow and deep holes that cannot be reached manually, burrs can be removed by inserting an electrode jig.

Achieving stable quality

By managing electrodes and jigs, anyone can perform uniform processing and maintain stable quality.

No secondary burrs

There is no secondary burr because burrs are melted by electrolysis.

Achieving manufacturing cost reduction

Since it is non-contact, the electrode jig can be processed without wear during normal use.

High operability

Easy to operate, anyone can operate it

High processing efficiency

The processing speed is fast, and simultaneous processing of multiple locations is possible.

Any material can be processed

As long as it is an object to be processed that is conductive, it can be processed regardless of the hardness of the material.

high processing capacity

Since no heat or mechanical force is required, no stress or strain is produced on the machined surface, and no work-affected layer is produced.

Spec

Device details

| Specification | Model | |||

|---|---|---|---|---|

| ECMB-N2 | ECMB-N1 | ECMB-OH | ||

| Equipment information | Body size (width x length x height) |

1,150×1,530×1,900 | 700×1,355×1660 | 500×1370×1600 |

| power supply | 30V200A | 25V200A | ||

| Tank capacity (L) | 300 | 100 | ||

| Option | Light Curtains | 〇 | ● | 〇 |

| Handy operation panel | 〇 | ● | 〇 | |

| Flowmeter | ● | ● | 〇 | |

| Incidental equipment | Centrifuge (filter) | 〇 | 〇 | 〇 |

| Filter press (filter) | 〇 | 〇 | 〇 | |

| Neutralization device | 〇 | 〇 | 〇 | |

| Cooling system | 〇 | 〇 | 〇 | |

| mist collector | 〇 | 〇 | 〇 | |

●=Standard equipment 〇=Option

To customers considering introduction

Information necessary for us to consider equipment

・Work piece drawing

・Work piece material (iron, stainless steel, aluminum)

・number of production

・Operating time

Items required for actual processing

・Electrode jig (designed by our company)

・Machining fluid (sodium nitrate, sodium chloride)

FAQ

※Please check before contacting us.

About inquiries/meetings

Please prepare the necessary information for us to consider, and contact us from "Inquiries".

Based on the information of the work to be processed, we design equipment and jigs, and propose even incidental equipment such as filtration equipment.

If you are in a hurry, please contact us by phone at the number below.

TEL:0465-82-0275(direct dial phone)

Yes. It is possible.Please contact us from "Contact Us".

Yes. It is possible.Please contact us from "Contact Us".

About processing burrs

Burrs are generated when processing using a cutting tool (drilling or lathe).

Also, the burrs we are targeting are metal burrs.

Mainly auto parts.Typical parts are listed below.

(Injectors, common rails, manifolds (ABS), connecting rods, crankshafts, pulleys, etc.)

Yes, there are.After electrolytic processing, exhaust gas (hydrogen, nitrogen, ammonia) and sludge (iron oxide, aluminum oxide, etc.) are generated.

In addition, metal ions are dissolved in the processing liquid and cleaning liquid, and it is necessary to ask an industrial waste disposal company to dispose of them.

Deburring is possible if the thickness of the root of the burr is within 0.05mm. Please contact us for larger burrs.

Yes. It is possible.when processing materials that contain a large amount of chromium such as stainless steel, Hexavalent chromium is generated.

Therefore, by changing a machining fluid from sodium nitrate to sodium chloride, it is possible to prevent the generation of hexavalent and reduce it to trivalent.

Electrolytic/Electrolytic deburring

Sodium nitrate or sodium chloride is used as a machining fluid .

A processing method that electrolyzes and dissolves metal burrs.

Electrolysis is chemical decomposition in which electrons are transferred between two electrodes (anode and cathode) through the working liquid to the workpiece.

At this time, at the positive electrode, electrons are taken away and oxidation occurs, and at the negative electrode, electrons are given and a reduction reaction occurs.

Yes.However, there is no problem in terms of accuracy.

It is flushed with a machining fluid as sludge.

Yes.

Yes it is.Pre-washing (removal of cutting oil) and post-washing (removal of electrolyte) are required.

Yes.If you leave it after washing, it will cause rust, so it is necessary to use anti-rust liquid etc.

If it is the electrolytic chemical deburring machine N1 (standard machine), it will take about 4 months.

Inquiry

For inquiries, please contact us from the inquiry page or by telephone (TEL: 0465-82-0275 (direct)).

copyright© Acritech Corporation. All rights reserved.